Ghilaf-e-Kaaba

The Ghilaf, which has lines from the Holy Quran embroidered on it, is made in the Dar-ul-Kiswa plant by hundreds of weavers at a cost of millions of Saudi Riyals. While the old Ghilaf e Kaaba would be disassembled and given to foreign dignitaries.

What is the kiswah?

The term kiswah in Arabic means a garment made to cover the body, but is also used for a silk cover for the Kaaba. It is affixed to the stone by means of copper rings below the marble base.

The cover of the Kaaba is made of 47 pieces of natural silk, each 98 cm by 14 m. The outer layer of Kisoh is made of 670 kg raw silk. Inside the cover is a strong cotton lining, which helps keep the silk on top.

In order to keep the kiswah in place, it also contains a belt piece that loops around. It is made up of 16 sections and is 46 metres long by 95 cm broad. Quranic passages are also stitched on it.

A dedication on one of the belt’s components lists the year the kiswa was manufactured.

The Kaaba door curtain is included in the kiswa. From 1300 to 1396, the embroidered curtain was initially hung over the Kaaba gate (819 in the Hijri calendar).

The curtain has a dedication phrase and many verses and religious phrases that are gold plated with silver threads.

Where is the kiswah made?

The Kiswah Al Kaaba Factory in Makkah has been making Kiswah for about 45 years. Owned and operated by the government of Saudi Arabia, it takes a full year to produce the cover. Of this, six to eight months are spent on embroidery alone.

The factory opened in 1977 and has about 200 employees, 114 of whom work solely on embroidery.

Creating the kiswah is a four-step process.

The imported Italian raw silk is first given a 22-hour black dye bath before being mechanically woven into simple black sheets. These are then divided; some will have black embroidery, while others will have gold and silver embroidery.

Following this procedure, the fabric is checked for resilience and density before being printed with a pattern that experts will then embroider over.

To suit the Kaaba, 54 separate pieces of cloth are made and then stitched together. On one of the biggest sewing machines in the world with a 16 by 14-meter sewing table, this phase is completed.

The business also creates a cover for usage during Hajj and the cotton lining for the kiswah.

Ahmed Hussain Ba Anter has worked at the factory for 26 of his 37 years of employment. He is an embroidery specialist who sewed the golden and silver threads in the writing on the kiswa.

He told The National, “I feel very honoured when my fingers hold the needles to stitch the Kaaba Kiswah.

He is currently employed as a supervisor with the division responsible for connecting the kiswah’s various portions. He has contributed over the years to the preparation of the Kaaba for Hajj.

“In 1441, 1436, and 1434, I three times clothed the Kaaba. The Kaaba will hopefully be decorated this year since it will be my final one before I retire. (The Gregorian calendar year 2020 is equal to the Hijri calendar year 1441.)

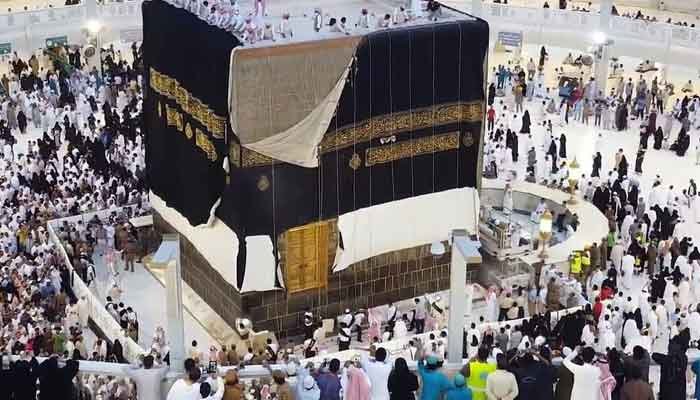

Ghilaf-e-Kaaba changing ceremony

Approximately 120 kg of pure gold, 100 kg of silver, and 670 kg of silk fibre were used to prepare the new cover. The Ghilaf-e-Kaaba has been prepared with an estimated cost of 7 million riyals.

After the Fajr prayer on the day of Arafat, which is a fundamental component of the Hajj, the Kiswa, or covering fabric, of the Kaaba is changed annually on the ninth Zilhaj.

Covers engraved with verses from the Holy Quran – produced by dozens of weaving experts at the Dar al-Kuswa factory at a cost of millions of Saudi Riyals. While the old cover of the Kaaba will be divided into pieces and gifted to foreign dignitaries.

The government officials and foreign dignitaries attending the ceremony which started after Fajr prayer that would take several hours till completion.

Hajj is one of the five pillars of Islam and involves a journey to Mecca to perform the religious rituals described in the Holy Quran. The new core is made with 120 kg of pure gold and 100 kg of silver imported from foreign countries and 670 kg of silk fiber brought from Italy.